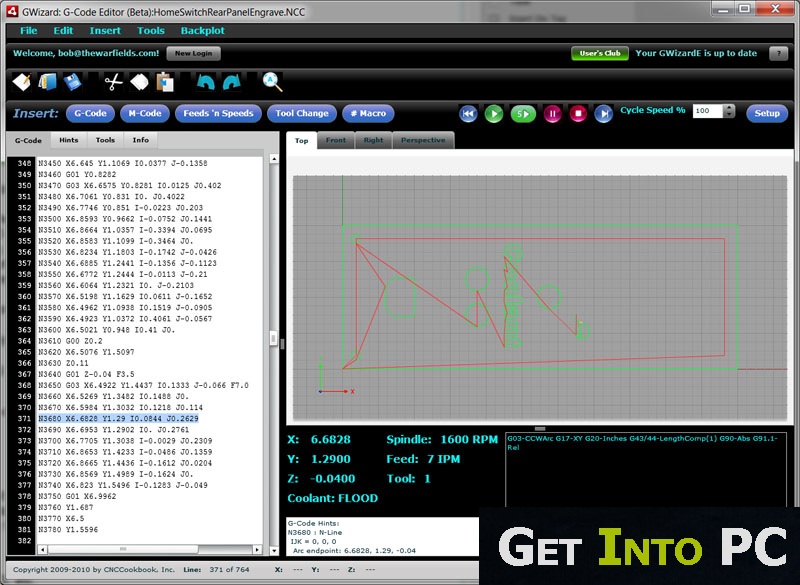

Whether you're a student, hobbyist, or business owner looking to move from a manual manufacturing process to the accuracy and repeatability of what CNC has to offer, you'll benefit from the in-depth information in this comprehensive resource. Helpful photos and illustrations are featured throughout. CNC Machining Handbook describes the steps involved in building a CNC machine to custom specifications and successfully implementing it in a real-world application. Drawings and CNC programs to practice on are also included for the reader.Ī Practical Guide to CNC Machining Get a thorough explanation of the entire CNC process from start to finish, including the various machines and their uses and the necessary software and tools. In so doing, the authors cover the level of CNC programming from basic to industrial format. The skill-set of CNC program writing is covered, as well as how to cut material during different operations like straight turning, step turning, taper turning, drilling, chamfering, radius profile, profile turning etc.

The authors explain about cutting parameters in CNC machines, such as cutting feed, depth of cut, rpm, cutting speed etc., and they also explain the G codes and M codes which are common to CNC. Basics of CNC Programming describes how to design CNC programs, and what cutting parameters are required to make a good manufacturing program.

Since then, CNC has become the dominant production method in most manufacturing industries, including automotive, aviation, defence, oil and gas, medical, electronics industry, and the optical industry. Thereafter, in the 1970's, an even larger revolutionary change was introduced to manufacturing, namely the use of the CNC machine (Computer Numerical Control). After these NC machine started to be used, typical profiles and complex shapes could get produced more readily, which in turn lead to an improved production rate with higher accuracy. Industry was boosted by the introduction of the semi-automatic manufacturing machine, known as the NC machine, which was introduced in the 1950's at the Massachusetts Institute of Technology in the USA. As a result, the production rate tended to be slow, production costs were very high, rejection rates were high and manufacturers often could not complete tasks on time.

Due to this, manufacturers could not make complex profiles or shapes with high accuracy. Before the introduction of automatic machines and automation, industrial manufacturing of machines and their parts for the key industries were made though manually operated machines.

0 kommentar(er)

0 kommentar(er)